Japanese Carbon Steel: A Glimpse into the Craft of Sharpness

Tamahagane, once regarded as the pinnacle of steel, with minimal impurities and about 1.5% carbon content, is the treasured steel used in the majority of traditional Japanese swords. However, innovations in metallurgy have enabled the development of steels that are even more superior for crafting knives and scissors.

What is Carbon Steel?

Carbon steel is made from iron and a small amount of carbon. Depending on the amount of carbon it contains, carbon steel is classified into four categories: low carbon steel, medium carbon steel, high carbon steel, and very high carbon steel. Low carbon steel contains 0.05% to 0.3% carbon, medium carbon steel has 0.3% to 0.5% carbon, high carbon steel contains 0.5% to 0.95% carbon, and very high carbon steel has 0.96% to 2.1% carbon.

High carbon steel is the most widely used carbon steel for making blades. Through heat treatment, it can maintain a good balance of hardness and toughness. Its hardness can be higher than stainless steel, ensuring a good edge retention. However, it has the drawback of being susceptible to rust.

Grades of Carbon Steel: Pricing, Proficiency, and Practicality in Yasuki Steel Selection

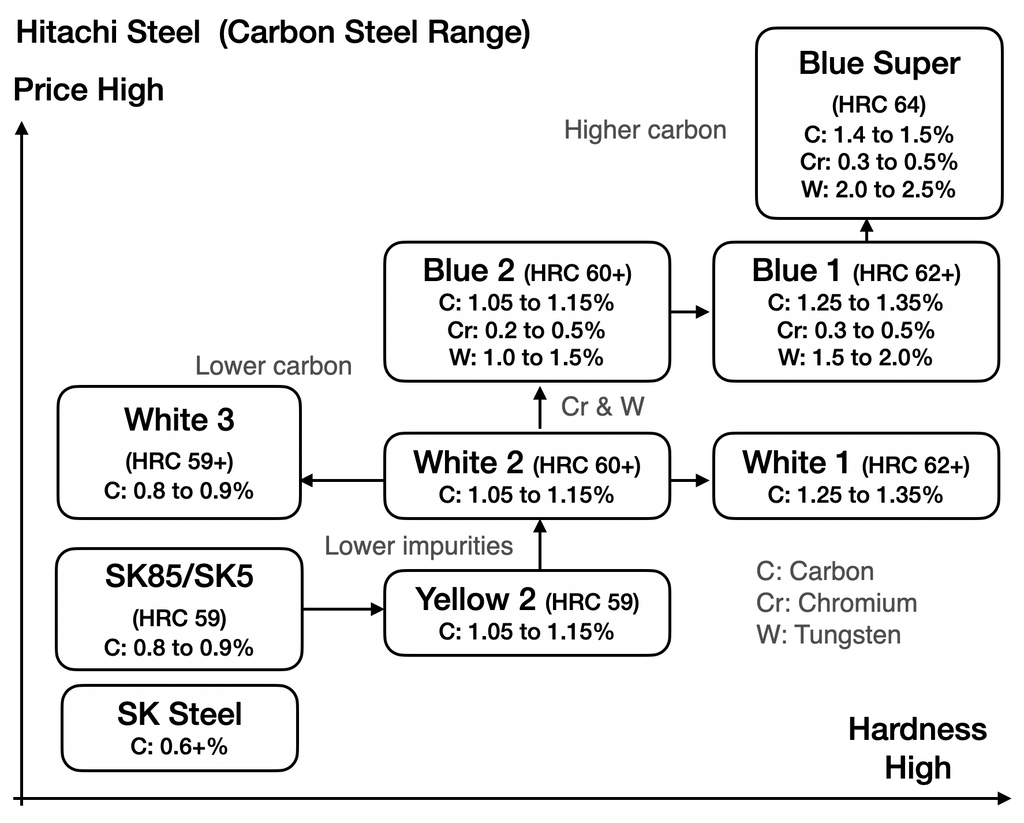

In the Japanese blade industry, the traditional 'Tamahagane' method has been industrialised by Hitachi Metals Ltd, resulting in the production of Yasuki Steel (YSS), which has become the mainstream. It is renowned for its applicability in crafting excellent knives and scissors, with different grades available based on impurity levels and alloy composition. These grades include:

- Blue Label (Ao-gami) Steel

- White Label (Shiro-gami) Steel

- Yellow Label (Ki-gami) Steel

This naming comes from the old practice at Hitachi Metals of distinguishing their steel types by sticking blue, white, or yellow papers as markers. Therefore, the colours themselves don't have a significant meaning.

The diagram above indicates that as the price of the steel material increases, so does its hardness. Consequently, it becomes more challenging to handle in terms of sharpening and maintenance.

Beginners who ambitiously purchase knives made of expensive steel such as White No.1 Steel or Blue No.1 Steel may find themselves unable to sharpen them, risking them becoming redundant. When it comes to expertly crafted Japanese knives and scissors, the price reflects the level of craftsmanship, which resonates with the skill level of the user.

Of course, price isn't everything. Depending on the type of Japanese blades, materials/ingredients, and usage environment, the ideal steel material may vary.

But when choosing the steel for a Japanese knife and scissors, the price is an inseparable consideration.

Sharpness & Edge Retention

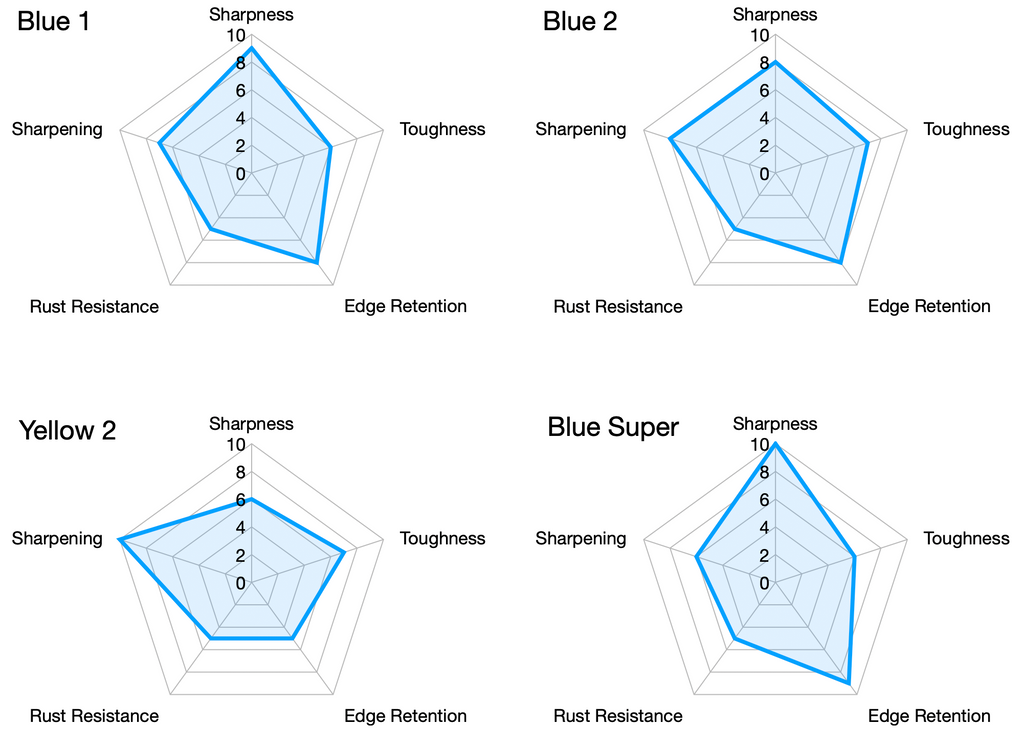

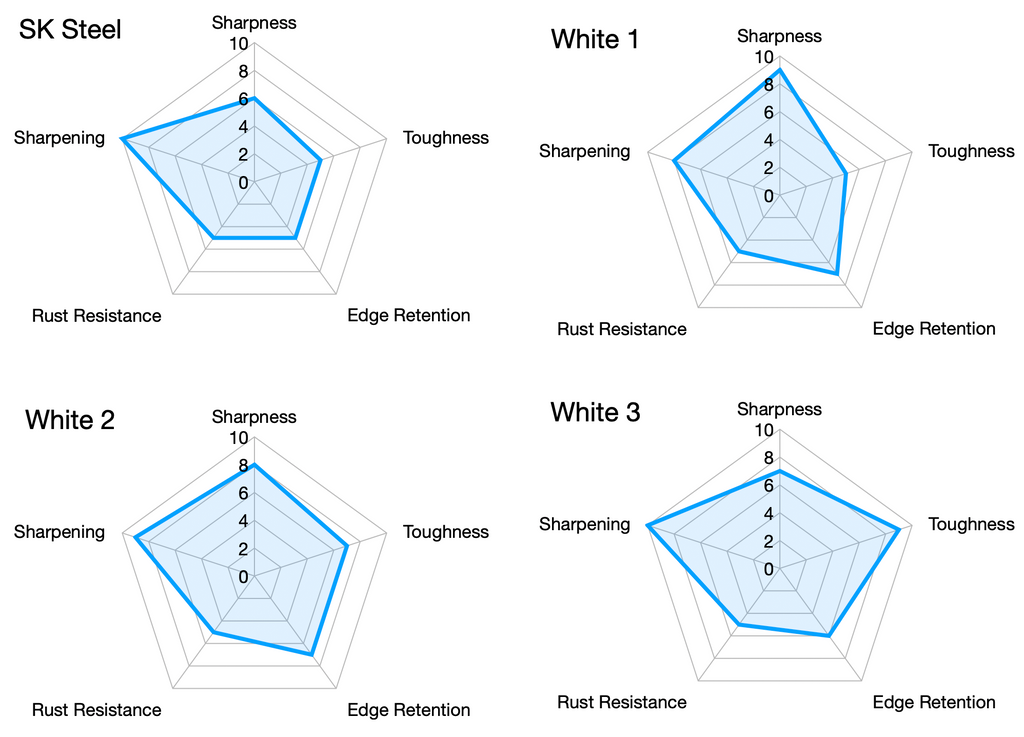

The most significant factors to consider when looking into the steel of a Japanese knife are its sharpness and the duration of its edge retention. Although the hardness of steel (carbon content) significantly influences sharpness, the added elements can alter its nature and characteristics.

For instance, while both White No.1 Steel and Blue No.1 Steel have the same carbon content of 1.30% (which can vary during manufacturing), the Blue No.1 Steel contains 0.40% chromium and 1.5% tungsten. This results in a different kind of sharpness compared to the keen edge of White No.1 Steel – it's challenging to describe, but it's a smoother kind of sharpness. Furthermore, the edge retention of Blue Label Steel tends to last longer than White Label Steel due to the benefits of the added chromium.

Ease of Sharpening

Generally, the more expensive the Japanese knife and scissors, the more difficult it is to handle. Expert sharpening skills are required, using appropriate sharpening stones and investing time and effort. Harder knives are more challenging to sharpen, whereas knives with a degree of toughness are easier.

Rust Resistance

The extraordinary sharpness of the top-tier carbon steel is undoubtedly appealing. However, depending on the workplace, regulations in the kitchen might only allow the use of stainless steel knives. Moreover, depending on the nature and environment of one's job, one might not have the time or resources to maintain carbon steel knives or scissors properly.

Using knives made from top-tier stainless steels like Silver No.3 Steel or VG-10 offers satisfactory sharpness and edge retention. Moreover, they significantly reduce maintenance efforts, allowing more time to prioritise other tasks. This peace of mind might directly influence one's creativity and overall work quality.

The Verdict: Sharpness or Low Maintenance?

When juxtaposing the unparalleled sharpness of carbon steel against the rust resistance of stainless steel, the choice becomes a matter of individual preferences, needs, and working conditions. Deciding between superior sharpness and ease of maintenance is pivotal for ensuring optimal utility and satisfaction from one’s tools. Balancing these aspects is crucial to making an informed decision that aligns with both personal preferences and professional requirements, offering a seamless blend of functionality, durability, and finesse.